Are you looking for a reliable manufacturer of rubber seals and rubber tube products

We can quickly provide customers with market analysis, technical support and customized services.

Get in touch

The rubber extrusion line is equipped with an advanced temperature control system, pressure control system and intelligent systems, ensuring uniform heating and stable extrusion of rubber materials during production, resulting in precise dimensions and high product consistency. The extrusion line can monitor the production status in real-time and adjust parameters, ensuring that every rubber product meets strict quality standards.

Designed for high-volume production, this line is perfect for large orders, ensuring fast delivery to meet the high-demand requirements of customers. It can produce thousands of meters per hour, significantly improving production efficiency.

Capable of extruding a variety of rubber materials, including neoprene, fluorocarbon rubber, EPDM, and more, the line is suitable for producing rubber hoses, sealing strips, and other industrial rubber products with different process requirements.

With an advanced electrical control system and automation technology, the extrusion line ensures high production stability, reduces human error, and minimizes production failure rates.

The fully automated production process reduces human intervention, increases production efficiency and safety, and lowers operational costs.

Our workshop is equipped with advanced automated braiding equipment, ensuring an efficient and stable production process. This enables us to produce high-quality rubber hoses and sealing strips in large quantities.

The workshop supports various composite materials such as polyester, polypropylene, and more, meeting diverse customer needs with customized braiding solutions.

With state-of-the-art equipment and a professional technical team, we deliver high-precision braided products, ensuring that each tube meets strict quality standards.

We offer flexible production capabilities, capable of handling both small and large-scale orders, with fast turnaround times to meet different project requirements.

The rubber liquid cooling tubes produced in our braiding workshop are widely used in liquid cooling systems, particularly in high-end electronic devices, AI servers, PC hardware, and other sectors, providing efficient heat dissipation solutions.

Custom tube diameter, length, and other specifications tailored to customer requirements.

Choose the most suitable materials based on application needs, such as high-temperature resistance, chemical corrosion resistance, and more.

Different braiding densities are available to ensure durability and stability during use.

Select appropriate braiding material colors, such as white, black, red, etc., based on customer preferences.

Our manual department focuses on comprehensive quality inspection for each product. Through strict manual testing procedures, we ensure every batch meets industry standards and is free from defects or flaws. From visual checks to functionality and precise measurements, we follow standardized processes to guarantee the delivery of high-quality products.

To ensure products arrive safely, our manual department handles precise packaging. Each product is packaged with suitable materials based on its characteristics, providing multiple layers of protection. We focus on every detail to guarantee your products arrive intact and undamaged.

We offer personalized services where products undergo final processing and packaging based on specific customer requirements. Whether it’s quantity, size, or custom markings, we provide flexible manual services to ensure the product fully aligns with customer specifications.

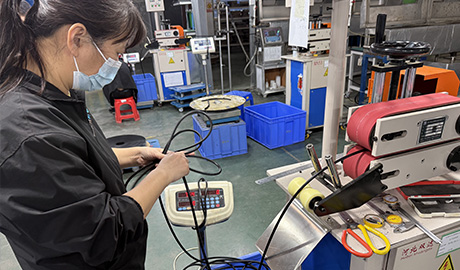

The incoming material inspection is the first gate in the production process of our rubber products, and it is also the basis to ensure the quality of the products. Through strict incoming material inspection, we are able to screen out quality raw materials and eliminate defective products.

Using a density meter, we accurately test the density of incoming rubber materials to ensure that each batch falls within the specified range. This helps maintain product consistency and stability.

We use a hardness tester to measure the hardness of the rubber materials, ensuring they meet the design requirements. Proper hardness is essential for the durability and adaptability of the rubber products.

Using a tensile testing machine, we test the tensile strength and elongation at break of the rubber materials, assessing their elasticity and durability. These tests ensure the reliability of the products in various applications.

We also test the tear strength of rubber materials to ensure they have sufficient resistance to tearing, enhancing the product's longevity and performance.

At the beginning of each production shift or when production conditions change, we meticulously inspect the first batch of rubber hose or sealing strip. This helps us to detect problems in the production process in advance and ensure that the subsequent products can meet the quality requirements.

We will visually inspect the rubber hose or sealing strip for damage, deformation, dirt and other cosmetic defects.

We will use caliper to detect the key dimensions of the rubber hoses or sealing strips to ensure that their dimensions meet the design requirements.

RESRUB is equipped with a state-of-the-art laboratory dedicated to product testing, R&D, and quality control. Our laboratory is equipped with advanced testing equipment, enabling us to conduct comprehensive physical, chemical, and mechanical property tests to ensure that every product meets international quality standards before leaving the factory.

We understand that choosing the right product for your industry is critical. That’s why we invite you to contact us. Whatever your goals, Linenwind will help you achieve them.

Learn MoreWe have a strong team that works closely with customers to meet market challenges and effectively meet specific needs. Our slogan is "Economical, Time-Saving, and Effortless Management" to win customer trust in your industry.

Start Customizing